COMPANY QA / QC PLAN

General

A&F Company Ltd shall establish, document, and maintain a quality control plan to ensure that all works conforms to specified requirements. This Quality Control Plan will be maintained by A&F and will comply with the requirements of the contract documents and the PROPONENT specifications and standards. The quality plan includes or references the quality procedures and outlines the documentation structure to be utilized, and this is explained in details in Quality Control Manual.

The quality plan shall function to provide confidence that:

-

■ The system is understood, implemented, maintained, and effective.

■ The products satisfy Contractor’s needs and expectations.

■ The needs of the environment are met.

■ Emphasis is placed on problem prevention rather than detection.

The plan is structured to establish control and assurance over all operational processes affecting the work and the final product quality.

The quality control plan elements can be classified into three specific categories:

-

♦ Management elements.

♦ Core process elements.

♦ Foundation elements.

The management elements are intended to oversee the continued application, suitability, and improvement of the Quality Control Plan. The core process elements deal with the physical developments of the contract products. The foundation elements support and reinfoPROPONENTe the management and core process elements. The quality control plan structure also takes into consideration the four basic facets of quality that are described as follows:

-

1. Quality due to definition of needs for the product

2. Quality due to product design

3. Quality due to conformance of product design

4. Quality due to product support

The Quality Control Plan consists of documented procedures that individually explain and detail the process and collectively coordinate all necessary processes required to accomplish the required tasks. The documented system addresses the policy and philosophy of A&F related to the various system elements of the Contract.

The Quality Control Plan this Contract requires that A&F define and document how quality requirements are to be met. Quality planning shall be consistent with all other requirements of the Quality Control Plan and documented in a suitable manner. The following will be considered in meeting specific project requirements:

-

I Preparation of quality control procedures

II Identification and acquisition of controls, equipment, and skills

III Compatibility of design, process, installation, service, inspection, and testing

IV Updating quality techniques

V Identification of measure requirements

VI Suitable verification at appropriate stages

VII Clarification of unacceptable standards

VIII Identification and preparation of quality records

The Quality Control Plan must define:

-

○ Quality objectives desire

○ Steps in operating procedures (flow charts)

○ Allocation of responsibility, authority, and resouPROPONENTes

○ Documented procedures to be applied

○ Inspection testing and audit programs

○ Procedures for modification to the quality plan

○ Methods for measuring quality objective achievement

Policy

The objective of the Quality Control Plan is to ensure that a high quality product is produced by A&F. Quality Control Personnel cannot inspect ‘Quality’ into completed work. They can only verify that good quality work is produced.

A&F shall provide a Quality Control team staffed by a Q.C. Manager and Q.C. Engineers as specified in the Contract Special Conditions, for each discipline; Civil, Electrical, and Mechanical who are qualified and equipped to the extent deemed necessary to support the quality control program. Such support facilities include and not be limited to:

-

1. Adequate materials testing services.

2. Qualified personnel separate from construction personnel to inspect and evaluate work performed.

3. Clearly defined acceptability criteria for all work performed.

4. Responsibility and authority of quality control manager and engineers to reject unsatisfactory work and have it corrected.

5. System for identifying, reporting controlling, processing, correcting and documenting of non-conformance and their resolution.

6. A system of reporting and recording to fully document inspections and tests made and quality levels attained.

Quality Standards

Compliance with Saudi Arabian Laws, Regulations, Applicable Codes and Standards is mandatory and take precedence over all other codes where conflicts arise.

A&F will maintain its Quality Control program to assure that all engineering, construction, materials, equipment and workmanship provided under this Contract are in compliance with provisions, applicable laws, codes, and standards, and sound engineering and construction practices unless specifically instructed by PROPONENT. The Quality Control Plan of A&F shall take full account of the requirements of such codes and criteria, together with the applicable documents of Engineering Standards.

The basic codes applicable to this Quality Control Plan are publications and documents of PROPONENT, including the special specifications listed in the Contract documents.

Organization

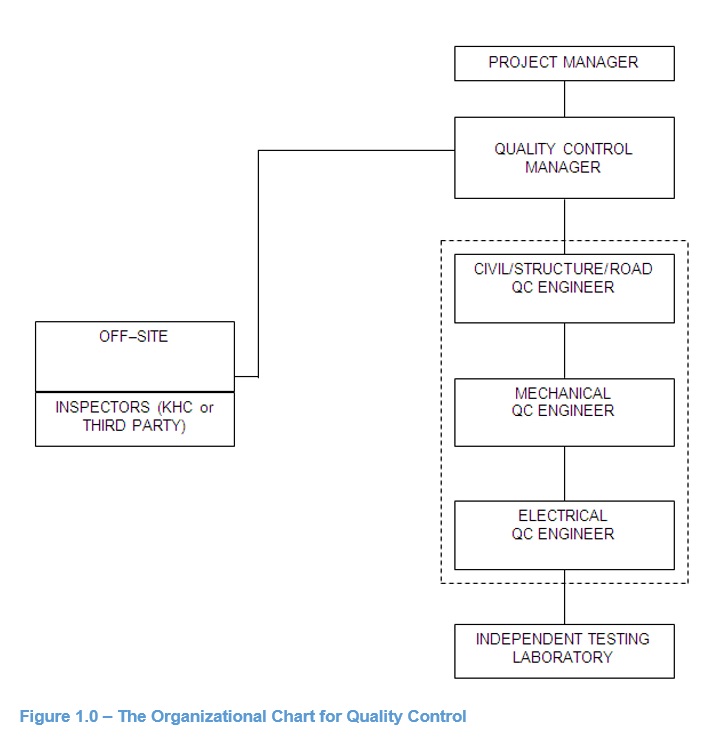

The Quality Control Organization will operate as a separate and independent Department within the Project Organization, reporting directly to the Project Manager. Its sole duty being to ensure conformance to applicable standards, specification and drawings with respect to materials, workmanship, construction, finish and functional performance, providing a statement that assures the end product complies with specifications and applicable standards and codes.

The typical A&F Quality Control Department will be divided into two sections, On–Site and Off–Site. Both Sections will report to the Quality Control Manager. The quality control and testing of permanent materials and equipment form Off–Site souPROPONENTes will be handled by the Off-Site Section under the responsibility of the Quality Control Engineer designated by the QC Manager from within or by a third party contracted by A&F with the approval of PROPONENT. Such material or equipment will be handled by the On-Site Section as they arrive on the project site for inspection, protection, storage, handling, and installation into the Permanent work. The On–Site Section will report to the Quality Control Engineer, and is further divided into:

-

(a) Testing – to include all laboratory and field materials testing services and by A&F QC staff or a third party contracted by A&F;

(b) Inspection – by the responsible QC discipline.

Figure 1.0 describes the organizational arrangement of the Quality Control Department within the Organizational Chart of A&F for the Contract No. 000-000.

It shall be the sole duty and responsibility of the Quality Control Manager and his staffs to organize, coordinate, conduct, and otherwise implement the Quality Control Plan as submitted by A&F and approved by PROPONENT. No other duties and responsibilities shall be assigned to the Quality Manager or his staff unless expressly authorized in writing by PROPONENT. The Quality Control Manager or his approved alternate shall be on the job site at all times while work is in progress. In the absence of the QC Manager, the Project Manager will be in – charge of the Quality Control operation.

A&F may assign direct employees or sub – contractor employees for certain types of work but in all cases, all employees whether direct or sub–contractor will work under the control of the Q.C. Manager.

Quality Control Personnel Authority:

-

♦ QC Manager may at anytime stop any work–in progress not fully complying with the Contract requirements.

In stopping any work, a notice stating the reasons for stoppage will be issued. Work will not proceed until

these unsatisfactory conditions have been rectified / corrected.

♦ Full authority on behalf of A&F to implement all aspects of the QC Plan including authority to reject non – complying

work and order of its removal is vested in the Quality Control Manager.

♦ Any deficiency will be corrected and the QC Manager shall be notified accordingly, before concealment of such work.

♦ QC Manager is authorized within his assigned areas of responsibility to approve/accept work that complies with the

specifications and agreed engineering standards.